ISO 9001 Quality Management System forms the basis of the professional management system.

Its goal is to ensure that companies create their own working systems, direct company employees towards the determined company goals and ensure the continuous development of the company.

ISO 9001:2008 can be applied to all types of organizations, from the agricultural sector to the industrial sector, from the public to the private sector.

ISO 9001 Quality Management System is a globally accepted quality management system published by the International Standards Organization that aims to increase customer satisfaction by meeting customer expectations, needs and legislative requirements.

The purpose of this standard is to reduce and eliminate errors and defects and, more importantly, to prevent errors and defects that may occur.

The standard is not directly related to product and service quality, but to the quality of the management system.

The ISO 9001 Standard is not a complete replacement of an organization's existing system, but rather an arrangement of the system in accordance with the standard requirements.

The ISO 9001 standard defines the requirements that must be applied to establish a quality management system. These requirements are based on eight quality principles. These principles are as follows;

1- Customer Focus: Organizations are dependent on their customers, so they must understand their customers' current and future needs well, fully comply with customer requirements, and strive to exceed customer expectations.

2- Leadership: Leaders organize and establish unity of direction and purpose. The leader must establish and maintain an environment within the company in which people are fully engaged and committed to achieving the organization's goals.

3- Employee Participation: People at all levels are an asset to the organization and with their full participation, their talents can be used productively for the organization's benefit.

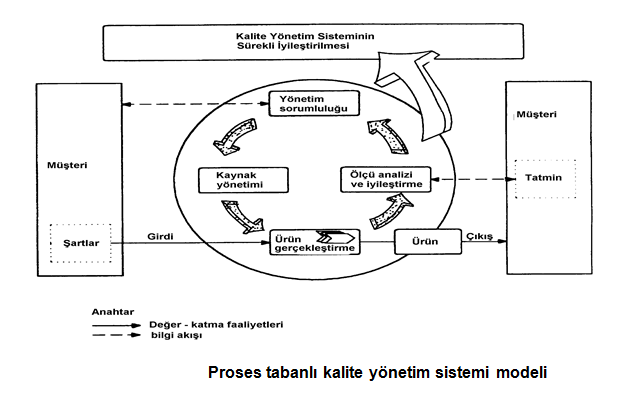

4- Process Approach: Successful results can be achieved much more effectively when activities and associated resources are managed as a process. P, Plan .. Determine Goals & Processes; U, Apply.. Apply Processes; K, Control.. Watch & Measure; HE, Take Precautions, Improve.. Ensure Continuous Improvement.

5- System Approach to Management:Determining, understanding and managing interrelated processes as a system ensures the effectiveness of organizations and provides efficiency in achieving goals.

6- Continuous Improvement: Continuous improvement of the overall performance of the organization should be a permanent goal of the organization.

7- Realistic Approach to Decision Making: Effective decisions must be made based on analysis of data and information.

8- Mutually Beneficial Supplier Relationships: An organization and its supplier are interdependent and have mutual interests to increase their capabilities in creating value and productive relationships should be established within this scope.

ISO 9000 STANDARDS SERIES

ISO 9000: It is a set of standards published by ISO that guides organizations in establishing and developing quality management systems to increase customer satisfaction.

ISO 9001: It is the standard that defines the conditions that must be applied during the establishment of Quality Management Systems and is subject to certification audit. It is the name of the document issued.

ISO 9001:2008: The ISO 9000 Standard is reviewed by ISO every 5 years and republished after making the necessary revisions in line with the opinions and needs of the practitioners. The number 2009 is the version date indicating that this revision was made and published in 2008 (ISO 9001:2008 version).

TS EN ISO 9000 standards consist of four basic standards. These are;

1. TS EN ISO 9000:2005 Quality Management Systems-Basic Concepts, Terms

2. TS EN ISO 9001:2008 Quality Management Systems - Requirements

3. TS EN ISO 9004:2009 Quality Management System-Guide for Improving Performance

4. TS EN ISO 19011:2011 Audit Guide for Quality and Environmental Management Systems

ARTICLE TITLES OF ISO 9001:2008 STANDARD

1- Scope

2- Referenced standards

3- Terms and definitions

4- Quality Management System

5- Management Responsibility

6- Resource Management

7- Product Realization

8- Measurement, Analysis and Improvement

CERTIFICATION PROCESS

An organization that wants to obtain certification according to the ISO 9001 Quality Management System Standard first signs a contract with the certification body authorized to issue this certificate.

Establishes the quality system in the organization in accordance with the requirements of the ISO 9001 Quality Management System Standard.

After the necessary preparations are completed, an audit is requested from the certification body.

As a result of the audit conducted by expert auditors, companies that are registered to have fulfilled the minimum requirements of the ISO 9001 standard are certified. The ISO 9001 Certificate is valid for a period of 3 years. During this period, an interim audit is conducted every year to ensure that the organization is carrying out its activities in accordance with the standard conditions, and at the end of the 3 years, a certificate renewal audit is conducted.

Benefits of ISO 9001 Quality Management SystemWith the internationally valid ISO 9001 certificate, the chance of competition in market conditions is increased. It is ensured that marketing activities are different from competitors. Institutionalization is achieved by creating a management standard. A systematic management approach is adopted. International commercial advantages are utilized. An increase is achieved in customer satisfaction and customer loyalty. A decrease is achieved in error rates, losses, and rework. Efficiency is ensured in input, production, and final controls. Ease is provided in the selection, evaluation, and follow-up of suppliers. The formation of documentation (infrastructure) that will ensure the standardization of business activities is ensured. Work done within the organization becomes independent of individuals. Past records are kept regularly. Productivity and profitability increase. A customer-oriented approach is adopted. Continuous improvement of general performance is ensured. Costs arising from errors and poor quality work are reduced. Intra-company communication is improved.