Today, traceability of agricultural products has become the most important issue in terms of ensuring food safety all over the world.

The most important item of the Good Agricultural Practices Standard is the establishment of the Traceability System.

The most important role in ensuring traceability is to keep accurate and simultaneous records of all production processes.

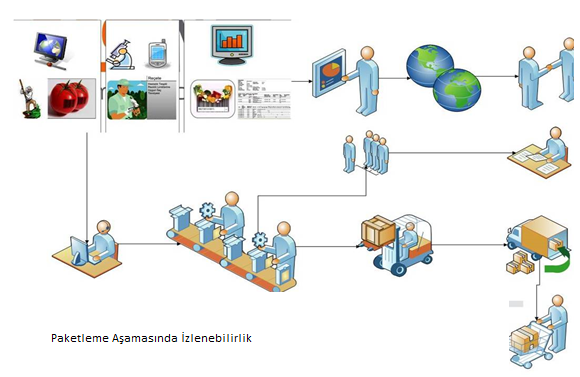

It is necessary to establish a reliable network between the producer and the end consumer and to facilitate the information flow.

When retrospective inquiries are made after detecting any problem (drug residue, quality, physical problems) that may arise in the product, it is vital to reach the origin of the product and who produced it in a short time and to get down to the source of the problem.

The most important source of making these inquiries and accessing all information from a single point will be to benefit from agricultural informatics.

Moreover, this information will help the retail industry not only in terms of food safety, but also in determining consumer demands, production planning and supply.

When the manufacturer detects a problem in the product he produces, he should be able to recall this product, and at the same time, the seller of the product should be able to access the information of the origin of the product and even the information of the workers in the facility that packaged this product.

Here's what to watch; production point, packaging point, logistics, market and final consumer.

The maximum information required to ensure traceability is listed below.

LAND RECORDS

A) MANUFACTURER IDENTIFICATION

The first step of the traceability system within the scope of Good Agricultural Practices should include the following information in order to identify the producer.

Manufacturer Name Surname, Identity Number, ÇKS Registration No, Address, Tel, Land Registry Parcel Numbers.

B) IDENTIFICATION OF THE PRODUCTION AREA AND THE PRODUCT

One of the important issues in establishing traceability within the scope of Good Agricultural Practices is primarily the definitions related to the production area and product. The following information should be included in this definition.

Product Type, Variety name to be produced, Area size, parcel code, production code, Soil and irrigation water analysis results of the land, Production area address, Consultant name, planting date, harvest date, harvest amount, planting interval, irrigation method, number of plants per decare ,production season.

C) CHEMICAL FIGHTING RECORDS USED IN PRODUCT PROTECTION

The most important chemicals used in a production area are insecticides, fungicides and herbicides used in the fight against pests and diseases.

Records of all kinds of pesticides used (in which production area, in what quantity, how much, on what date, active substance, for which disease or pest, harvest waiting period, license date, invoice number, applied by whom and recommended by whom) should be kept. .

D) FERTILIZER RECORDS

All kinds of fertilizers used (when, how much, in which production area it was applied to the area, its content, trade name, by whom it was applied) should be kept.

E) HARVEST RECORDS

When, in what quantity and what quality the product was harvested, by whom it was collected, to which person it was sold, and the invoices of each lot should be recorded.

F) PACKAGING, PROCESSING, STORAGE RECORDS

Records of the entire process from the acceptance of the product to the transportation stage (who processed, what chemicals were used, which pallets were palletized, which store and market it was sent to, transportation vehicle information, and in-vehicle temperature measurements should be kept.

G) ANALYSIS

The results of the chemical, physical, chemical and microbiological analysis of the soil used in production, the physical, chemical and microbiological analysis of the irrigation water, and the results of the residue (pesticide residue analysis) of the harvested product should be recorded.